The Future of Maritime Manufacturing

In an era where technological advancements frequently reshape industries, the maritime sector is now catching the wave of innovation through 3D printing. As I delved into developments in the Netherlands, I encountered a bold vision: Dutch firms are looking to revolutionize boat manufacturing by automating production processes that have long relied on traditional craftsmanship.

The Breakthrough Material

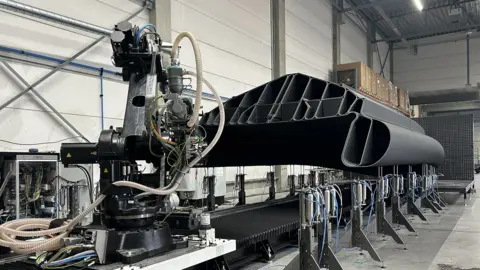

At the heart of this transformation is a new material blend hailed for its durability and resistance to the rigors of the marine environment. A combination of thermoplastics and fiberglass, this innovative mix has been meticulously developed by Maarten Logtenberg and his team at CEAD, enabling the printing of robust boat hulls without the need for additional coatings to guard against sunlight.

“We're automating almost 90% of the boat-building process, and in superfast time,” Logtenberg states confidently. “Normally it takes weeks to build a hull. We print one now every week.”

Time Efficiency Over Tradition

This leap forward in production efficiency is not just about saving time; it's about redefining the way we think about boat manufacturing. Historically labor-intensive, the traditional methods face challenges in keeping up with modern demands. The shift towards additive manufacturing—often termed 3D printing—promises a streamlined process where intricate designs can be realized with minimal human intervention.

CEAD's advances are particularly noteworthy; after months of tweaking, they now boast a factory where a print job takes as little as four days to yield a complete hull. For an industry that typically operates on manual labor and lengthy timelines, these advancements could mean a significant reduction in production costs and time.

Market Acceptance: The Key to Progress

Despite the technological potential, the bedding of 3D printed vessels in the market remains a fluid challenge. Logtenberg acknowledges that market acceptance is crucial and that customers are hesitant to invest in unproven technologies. “People are not going to invest and then just hope that the market will develop,” he explains.

Competitive Potential in the Leisure Market

Nearby, a similar initiative is unfolding at Raw Idea in Rotterdam, where its 'Tanaruz' brand seeks to impact the leisure boating sector. Their strategy? Utilize a combination of recycled materials and innovative design to create boats that appeal both to eco-conscious consumers and those fascinated by technology.

“Consumers are hesitant [because of the novelty], but the rental market is really keen,” says Joyce Pont, Raw Idea's managing director. “It's marketing; you can go to the socials and say, 'we've got a 3D printed boat,' and everybody wants to look at and touch that boat.”

The Path Ahead: Challenges and Optimism

As these companies navigate the waters of innovation, they also engage closely with regulatory bodies to ensure compliance and safety standards. Pont points out the cautious optimism among stakeholders, noting that actual boat production and market interest are beginning to align.

The use of 3D printing in the maritime industry is still in its infancy, and while Pilot projects signal promising beginnings—such as CEAD's prototype for the Dutch Navy, created in just six weeks—there are hurdles to overcome.

Regulatory Landscape and Future Prospects

The marine industry faces stringent regulations, and the increasing complexity of materials used in 3D printing presents both an opportunity and a challenge. As companies like Raw Idea and CEAD work on innovation, they are also in constant dialogue with European regulators to find common ground on standards for these new vessels.

Conclusion: Riding the Tide of Change

While the collective view among some experts is that entirely 3D printed ships are a distant goal—可能在二十年后才能实现—the enthusiasm surrounding advancements in 3D printed boats is palpable. For companies like CEAD and Raw Idea, the next few years will be critical. If they successfully navigate both consumer interest and regulatory challenges, the future could indeed hold an era where 3D printing becomes the norm in boat manufacturing.

Source reference: https://www.bbc.com/news/articles/c751xw96e9yo